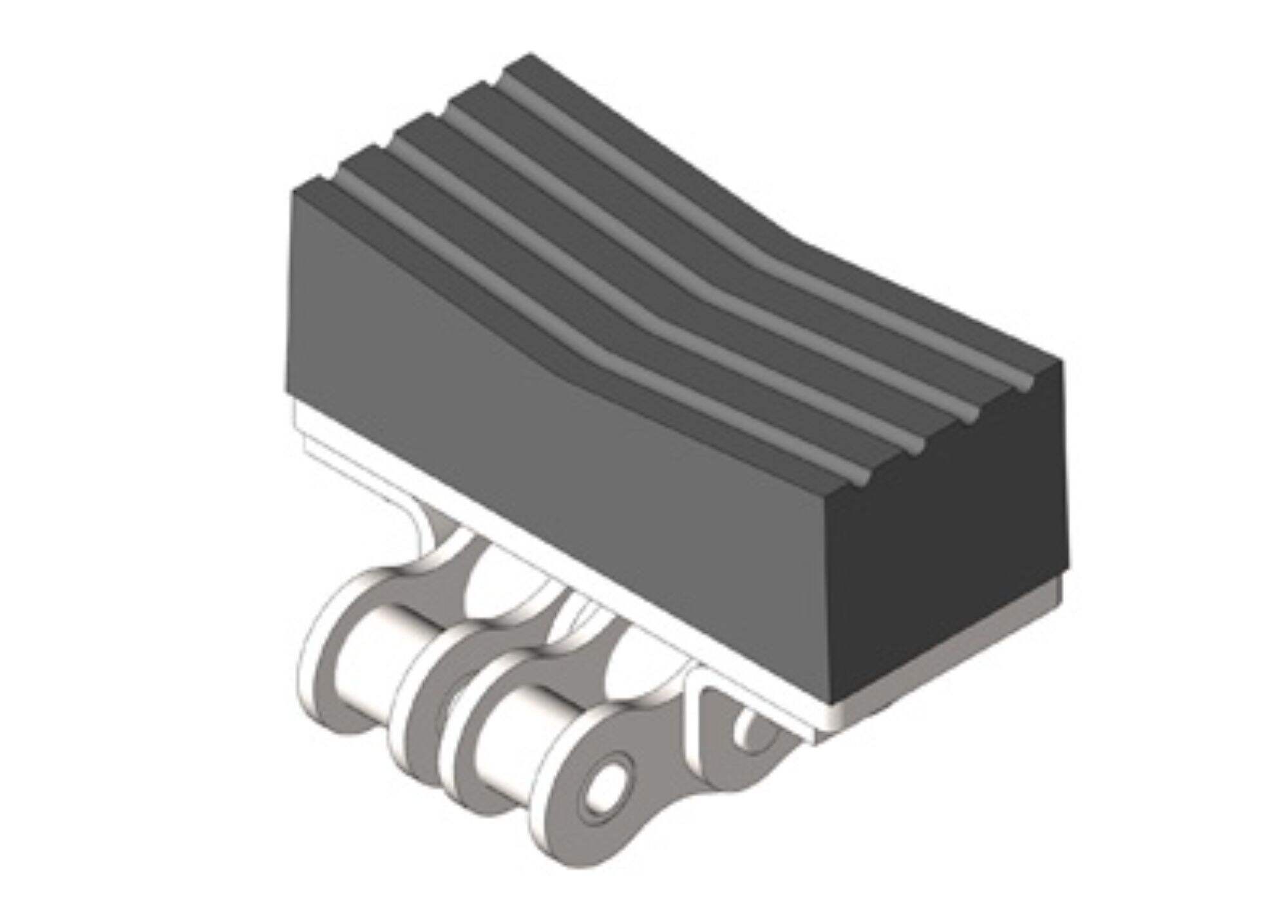

A duplex roller chain may appear to be a complex piece of kit, but in reality it is very simply, once you become acquainted with it. It’s like the chain of a bicycle, only much bigger. This chain is widely used in industrial machinery for transmitting power. It consists of a linked series of metallic links with wheels to roll easily and effectively.

There are many advantages to using a duplex roller chain in industrial machinery. First off, it's critical for good power transfer, that is for making the machine run easily and well. It’s quite a durable piece of equipment and should last a good amount of time, which will save you money in maintenance and replacement costs. Moreover, duplex roller chains have the ability to handle heavy loads and high-speed rotations, which makes them well-suited for various industrial applications.

The well-functioning of a duplex roller chain is dependent on adequate maintenance for efficiency and longer life. One key point is to keep the chain oiled to minimize friction and wear. Also check chain for damage or wear, and replace worn or damaged parts immediately. Aside from lubrication, a spotlessly clean chain will increase performance of the engine.

There are a variety of styles of duplex roller chains, which are interdit with for different types of applications. For instance, certain chains are stainless steel for corrosive conditions while other types are heat-treated for being employed at high temperatures. There are also chains specifically for certain industries, food processing or automotive manufacture for example. Selecting the appropriate chain type for your application is essential to achieve the best possible performance and service life.

Duplex Roller Chain Design – Key Elements Duplex roller chain is available with a few outstanding features that allow it to be chosen for industrial applications. Some of those features include precision honing for smooth operation, heat treat for strength and longevity, and pre-lube so there is no initial break-in period. In addition, duplex roller chains can withstand heavy loads and high speeds, and are used in a broad variety of applications.

Abundant Industry Experience: Established in 2005, with its factories dating back to 2000, the company has over 25 years of manufacturing expertise in various fields including gearboxes, chains, transmission shafts, and transmission line parts. This has enabled it to accumulate a profound industrial heritage and better handle diverse production and market challenges.Professional Customization Capability: Focused on the development of customized OEM products, it can conduct personalized production based on specific customer requirements, meeting the diverse needs of the market. It demonstrates strong flexibility and adaptability in market competition.Excellent International Reputation: Thanks to its sincerity towards customers, high sense of responsibility for orders, and long-term cooperation experience with foreign clients, the company's products are widely popular in the European market. It has won the trust of customers worldwide, and its brand influence is continuously expanding.

Diversified Product Portfolio: Covering a wide range of products such as various types of conveyor chains,PTO shafts, sprockets, gears, couplings, V-pulleys, , and worm gear reducers. These products are widely applied in industries like sugar, cement, mining, food, water, wood, automotive, and palm oil, providing one-stop product solutions.High-Quality Product Assurance: The production process employs modern equipment manufacturing and strict quality control measures. This ensures stable and reliable product performance, reduces customers' failure and maintenance costs during use, and improves production efficiency.

Quality After-Sales Support: Possessing a professional engineer team for after-sales service, it can promptly address problems encountered during product usage, offer technical support and solutions to customers, ensure the continuity of production, and enhance customers' confidence in using the company's products.Rich Information Provision: With a news and blog section, it shares industry knowledge and FAQs, such as chain rust issues, common problems and solutions for conveyors, chain quality judgment methods, and gear tooth number design. This provides customers with valuable technical information and purchasing guidance, helping them better understand the products and industry trends, reflecting the company's professionalism and care for customers in the industry.

Advanced Production Equipment: Utilizing modern equipment in the production process to ensure high-precision and high-quality production of products, improve production efficiency and product consistency, and maintain a technological edge in the fierce market competition.Technology Research and Development Capability: Based on long-term industry experience and customized product development capabilities, it has a certain technology research and development team and capabilities. It is able to continuously improve product design and production processes to adapt to new market demands for product performance and technology.

Copyright © Hangzhou Ocean Industry Co., Ltd. All Rights Reserved