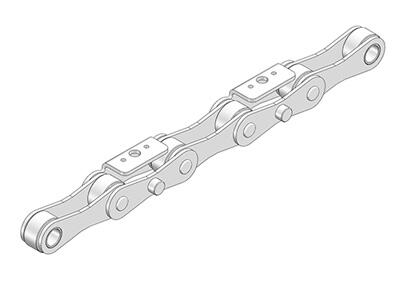

Chain conveyor belts are like magic carpets for factories highly efficient devices for transporting items from one location to another. It's like a long belt that moves things along a smooth path! These conveyor belts contain lots of small links connected to each other in a strong but flexible arrangement that helps to facilitate the movement of items on the conveyor. Ocean Sprocket is one of the firms that manufactures world class conveyor chains. These belts are used in many factories all over the world, and they help make things quick and safe for everyone working there. It can be considered as large chains that continuously move throughout the time to transport goods. Typically they are made of material such as metal or plastic, as these are very strong and sturdy. This prevents items from getting damaged while being moved and therefore, conveyor belts have parts called attachments to grab onto the items being moved and pull them through the belt. They make great choices for transporting large or heavy items that would be difficult to carry by hand. For instance, consider juggling boxes of toys, or large pieces of machinery this is where chain conveyor belts really perform their magic!

Ocean Chain belt conveyor line in factories have several advantages. Moving an object In one place to another is where they can save lots of time and energy. Where such items are instead placed on a conveyor belt, workers can devote themselves to other, more important tasks than pushing heavy carts or carrying things around. In this manner, they can work much freely and get their work done faster. Safety is another key benefit that chain conveyor belts provide for worker safety. These belts remove the heavy lifting from the bodies of workers. Instead of lifting or bending down to move items, workers can leave some products on the conveyor belt and let it do the work. This minimizes the chances of back pain or muscle injuries, enabling workers to perform their jobs healthily and safely.

The time before chain conveyor belts was a slow and hard job of moving things in a factory. Workers would have to physically transport heavy objects from one area to another which can be time consuming and very tiring. This process has also become easier and faster with the invention of the chain conveyor belts. And now, automated paint conveyor system workers no longer need to struggle to move items, the conveyor belts do the heavy lifting.

They have indeed revolutionized the way material is conveyor line design handled in factories. A lot of them give a fast and reliable means of moving goods from point A to point B. That means These types of belts can also be customized for the particular requirements of individual factories. This Ocean allows factories to establish a conveyor belt system that is tailored to suit the needs of their products and workflow, which in turn makes chain conveyor belts a versatile tool in a wide variety of industries.

Enhances Efficiency Ocean Chain Conveyor belts are an important factor in making factories effective. First, they can increase the speed of production in general by moving products quickly between each workstation. Transporting items quickly allows workers to go about their job duties at a more brisk pace and helps them do so more efficiently, boosting productivity across the board. This matters greatly in bustling factories that rely on the hour to hour end game of dispatching products to customers. There are systems in place that assist in conveying items through chain conveyor belts wherever mistakes can be avoided. Since the sprocket conveyor belt follows a predetermined course, there is a smaller opportunity for objects to get dropped or lost. This makes the work in the factory much cleaner and more organized, meaning everyone can work better together.

Abundant Industry Experience: Established in 2005, with its factories dating back to 2000, the company has over 25 years of manufacturing expertise in various fields including gearboxes, chains, transmission shafts, and transmission line parts. This has enabled it to accumulate a profound industrial heritage and better handle diverse production and market challenges.Professional Customization Capability: Focused on the development of customized OEM products, it can conduct personalized production based on specific customer requirements, meeting the diverse needs of the market. It demonstrates strong flexibility and adaptability in market competition.Excellent International Reputation: Thanks to its sincerity towards customers, high sense of responsibility for orders, and long-term cooperation experience with foreign clients, the company's products are widely popular in the European market. It has won the trust of customers worldwide, and its brand influence is continuously expanding.

Diversified Product Portfolio: Covering a wide range of products such as various types of conveyor chains,PTO shafts, sprockets, gears, couplings, V-pulleys, , and worm gear reducers. These products are widely applied in industries like sugar, cement, mining, food, water, wood, automotive, and palm oil, providing one-stop product solutions.High-Quality Product Assurance: The production process employs modern equipment manufacturing and strict quality control measures. This ensures stable and reliable product performance, reduces customers' failure and maintenance costs during use, and improves production efficiency.

Quality After-Sales Support: Possessing a professional engineer team for after-sales service, it can promptly address problems encountered during product usage, offer technical support and solutions to customers, ensure the continuity of production, and enhance customers' confidence in using the company's products.Rich Information Provision: With a news and blog section, it shares industry knowledge and FAQs, such as chain rust issues, common problems and solutions for conveyors, chain quality judgment methods, and gear tooth number design. This provides customers with valuable technical information and purchasing guidance, helping them better understand the products and industry trends, reflecting the company's professionalism and care for customers in the industry.

Advanced Production Equipment: Utilizing modern equipment in the production process to ensure high-precision and high-quality production of products, improve production efficiency and product consistency, and maintain a technological edge in the fierce market competition.Technology Research and Development Capability: Based on long-term industry experience and customized product development capabilities, it has a certain technology research and development team and capabilities. It is able to continuously improve product design and production processes to adapt to new market demands for product performance and technology.

Copyright © Hangzhou Ocean Industry Co., Ltd. All Rights Reserved