Drive pulleys are essential components of many machines and vehicles. They assist in transferring power from one section of the machine to another. This power movement is extremely critical for the proper operation of things.

They are commonly fabricated from durable metals or plastics. They have a shape that is unique for the purpose of clutching belts or chains. As the pulley rotates, it moves the belts or chains attached to it. And this movement does the work of transferring power from here to there.

Drive pulleys in machines help everything run smoothly. They are often used the direction and how fast things move. The conveyor line, for instance, in a car, transfers power from the engine to the wheels of the automobile, so the automobile can move forward and backward.

Here are the considerations to keep in mind when choosing the drive pulley for a machine. First, think about how big the pulley was. A larger pulley can often transfer more power while a smaller pulley can help to increase velocity.

Drive pulleys are what power motion and transfer motion from one part of a machine to another. The pulley itself turns, which moves belts or chains to move other parts of a machine. Moving like this is what keeps the machine running properly.

Drive pulleys are also used to drive some motions and speed directions. If we use a different size or shape pulley, we can change the speed and velocity at which an object moves. This is crucial to ensure a machine works safely and well.

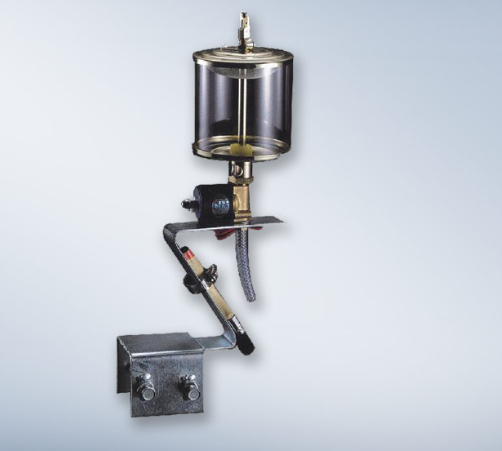

Like any machine component, drive pulleys require maintenance to function smoothly. That may involve cleaning and oiling them periodically to prevent them from wearing out. It’s also vital to check for any symptoms of damage or trouble and to correct them as soon as possible.

Quality After-Sales Support: Possessing a professional engineer team for after-sales service, it can promptly address problems encountered during product usage, offer technical support and solutions to customers, ensure the continuity of production, and enhance customers' confidence in using the company's products.Rich Information Provision: With a news and blog section, it shares industry knowledge and FAQs, such as chain rust issues, common problems and solutions for conveyors, chain quality judgment methods, and gear tooth number design. This provides customers with valuable technical information and purchasing guidance, helping them better understand the products and industry trends, reflecting the company's professionalism and care for customers in the industry.

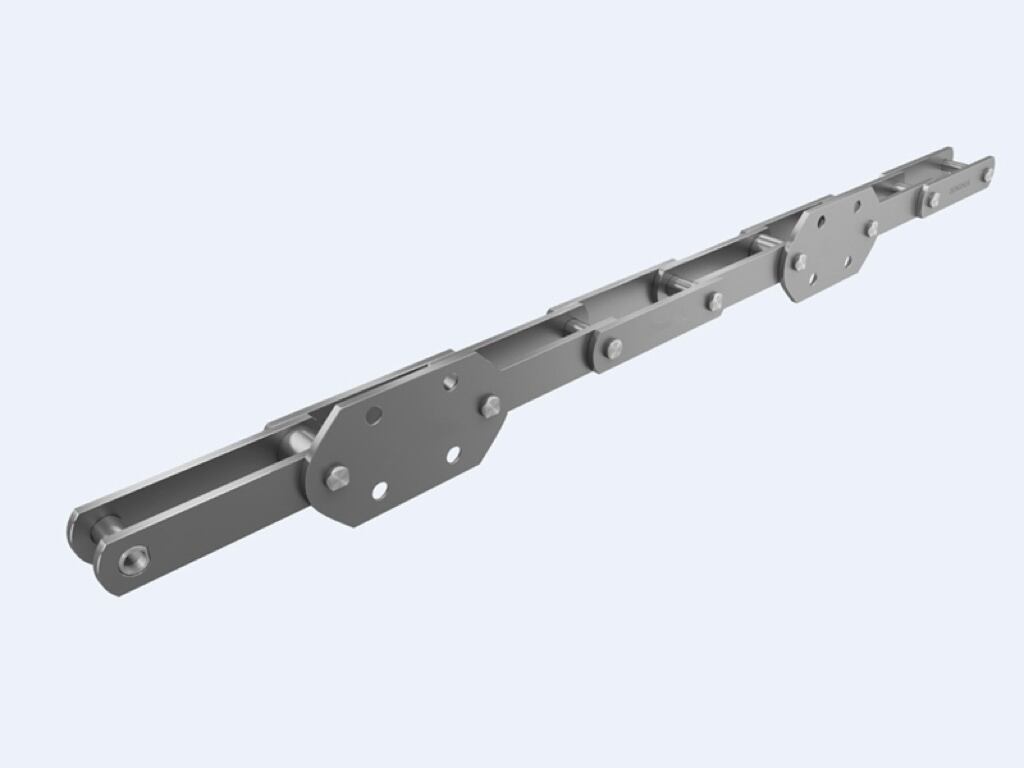

Diversified Product Portfolio: Covering a wide range of products such as various types of conveyor chains,PTO shafts, sprockets, gears, couplings, V-pulleys, , and worm gear reducers. These products are widely applied in industries like sugar, cement, mining, food, water, wood, automotive, and palm oil, providing one-stop product solutions.High-Quality Product Assurance: The production process employs modern equipment manufacturing and strict quality control measures. This ensures stable and reliable product performance, reduces customers' failure and maintenance costs during use, and improves production efficiency.

Advanced Production Equipment: Utilizing modern equipment in the production process to ensure high-precision and high-quality production of products, improve production efficiency and product consistency, and maintain a technological edge in the fierce market competition.Technology Research and Development Capability: Based on long-term industry experience and customized product development capabilities, it has a certain technology research and development team and capabilities. It is able to continuously improve product design and production processes to adapt to new market demands for product performance and technology.

Abundant Industry Experience: Established in 2005, with its factories dating back to 2000, the company has over 25 years of manufacturing expertise in various fields including gearboxes, chains, transmission shafts, and transmission line parts. This has enabled it to accumulate a profound industrial heritage and better handle diverse production and market challenges.Professional Customization Capability: Focused on the development of customized OEM products, it can conduct personalized production based on specific customer requirements, meeting the diverse needs of the market. It demonstrates strong flexibility and adaptability in market competition.Excellent International Reputation: Thanks to its sincerity towards customers, high sense of responsibility for orders, and long-term cooperation experience with foreign clients, the company's products are widely popular in the European market. It has won the trust of customers worldwide, and its brand influence is continuously expanding.

Copyright © Hangzhou Ocean Industry Co., Ltd. All Rights Reserved