Precision Grades of Gear Racks: DIN 5 vs. DIN 10 for Industrial Robots

Factory robots are very useful in manufacturing. They assist with tasks that are either too dangerous or repetitive for humans to perform. These are robots that require gears to articulate their arms and do their jobs effectively. Gear racks are an integral part of this type of gears and they have to be perfectly precise for the robots to perform properly.

Advantages

“Knowing the importance of accuracy in gear racks for industrial robots is like knowing the importance of tying your shoelaces properly in order to run without tripping.” If the gear racks aren’t precise, the robots may not be able to move their arms or do their jobs properly. To ensure that robots operate smoothly, gear racks are held to precision grades such as DIN 5 and DIN 10.

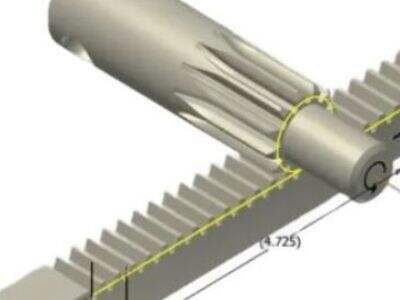

DIN 5 versus DIN 10 gear racks is kinda like seeing if a ruler can draw a straight line straight enough. DIN 5 gear racks are finer than DIN 10 gear racks. That’s because DIN 5 gear racks ensure that robots move more smoothly and perform their work more accurately.

Benefits

How precision grades affect robots’ performance is sort of like how being precise with your measurements in baking can help your cakes turn out better. If the gear racks in robots are more accurate, they can move more quickly and do their jobs more precisely. It helps robots work better and complete tasks more quickly.

Compared to DIN 5 and DIN 10 gear racks, it’s like comparing a superhero with normal people! DIN 5 gear racks are kind of like superheroes because they’re the absolute precise best at helping a robot do things with maximum accuracy. DIN 10 gear racks are all right, they are however not as accurate as DIN 5 gear racks.

The advantage of using high precision gear racks for industrial robots is like the advantage of driving a fast car in comparison with a slow car. It may be a little more expensive to use DIN 5 gear racks, but it’s worth it. DIN 5 gear racks enable industrial robots to work faster and more reliably, which enables factories to produce goods more efficiently.

Summary

The above show the importance of high precision for the performance of gear belt conveyor line of industrial robots. DIN 5 racks are more accurate than DIN 10 racks, so robots get better performance. The use of gear racks of higher accuracy class such as DIN 5 can, with suitable gears, provide significant improvements of industrial robots. Just as tying your shoelaces a certain way helps you run without tripping, perfectly angled gear racks are key in order for robots to do their jobs accurately and promptly.

EN

EN

AR

AR

FI

FI

NL

NL

DA

DA

CS

CS

PT

PT

PL

PL

NO

NO

KO

KO

JA

JA

IT

IT

HI

HI

EL

EL

FR

FR

DE

DE

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

FA

FA

MS

MS

HA

HA

KM

KM

LO

LO

NE

NE

PA

PA

YO

YO

MY

MY

KK

KK

SI

SI

KY

KY