Single roller chains are a key part of a lot of the machinery and equipment we use in countless industries today., we take a closer look into what a single roller chain is as well as the benefits of using a single roller chain in any industrial applications, practical advice concerning its maintenance to ensure its long,service life, as well as how to effectively select the correct size and type for each of your equipment, and tips on dealing with some of the common issues with the chain and how to troubleshoot these problems.

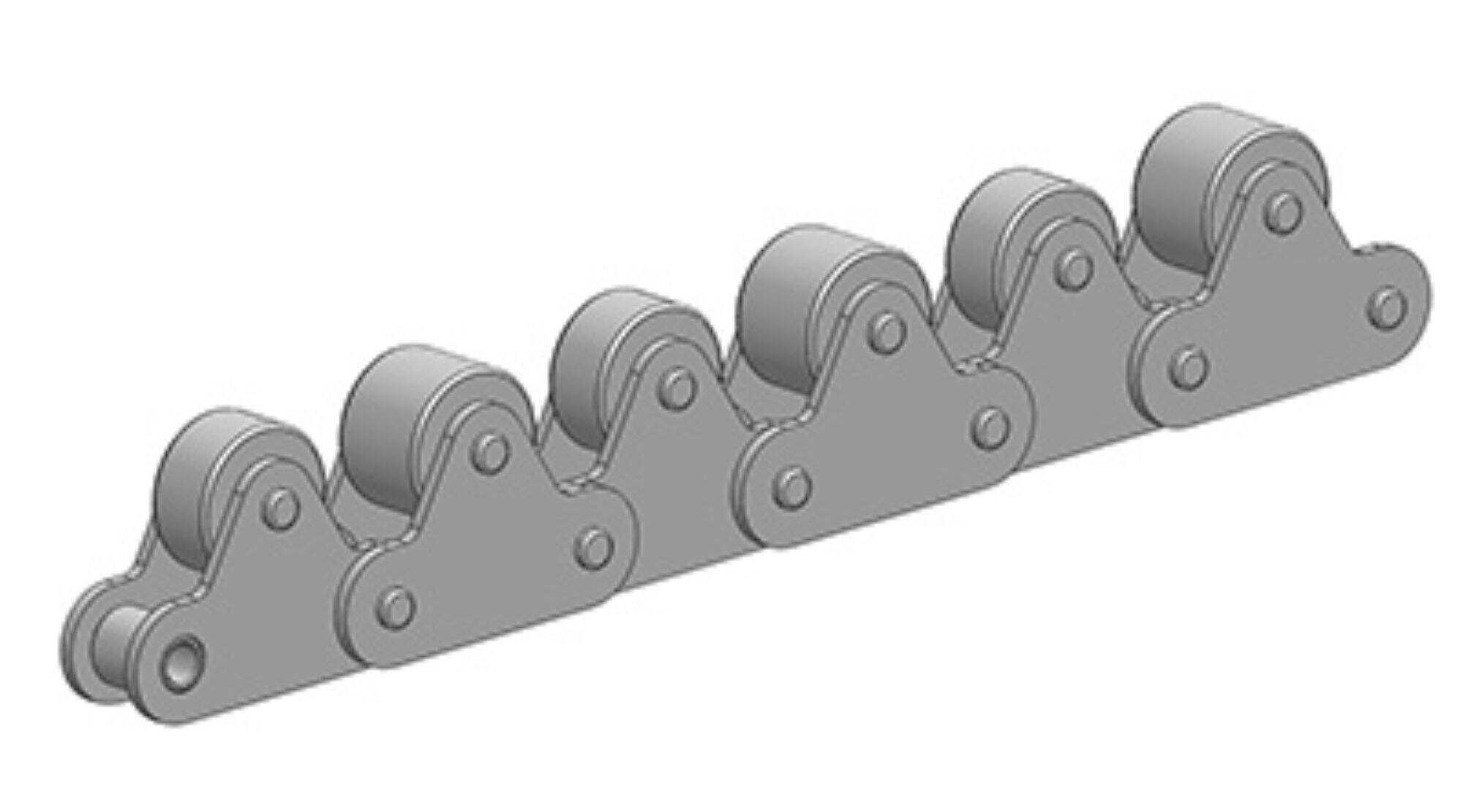

A roller chain single is a chain which consists of both roller links and pin links joined together. They are commonly used for transferring energy from one part of a machine to another, as we have seen in conveyor belts, bicycles and some factory machines. The chain links have rollers to minimize friction and wear and promotes longer operating life.

There are several benefits to using a single roller chain in an industrial setting, not the least of which is the chain's strength. These chains are manufactured with solid rollers and bushings for strength and durability, and are between 30-40% heavier than lightweight chains. They are also fairly simple to install and maintain, minimizing the amount of time you'll spend with downtime so that you can keep your operation running.

By inspecting and maintaining your single roller chain, you can ensure that it lasts as long as possible. This will involve ensuring that the chain is adequately lubricated, inspect for wear or damage and replace any worn or damaged links as required. It is important to take the chain off the cassette and clean it often to prevent dirt and other objects from wearing it out faster.

Size and Type One you've determined that a single row roller chain is the best choice for your equipment, the next step is to find the right size and type of chain for the job. Certainly the amount of power that needs to be transmitted, the speed the chain will be moving, and the conditions in which it will operate. Proper chain size and type selection can provide significant beneficial impacts on achieving smooth performance and avoiding problems like chain breakage and chain failure.

Just like any other equipment there are problems that you might encounter with a single roller chain. Some typical issues you will come across are: chain growth, roller wear and stiff or sticky links. The solution might be to adjust the tension on the chain, change any chains that may be worn or bent, or clean and oil the chain. If the issue continues maybe you need to buy new chain for the sake of your gear...

Advanced Production Equipment: Utilizing modern equipment in the production process to ensure high-precision and high-quality production of products, improve production efficiency and product consistency, and maintain a technological edge in the fierce market competition.Technology Research and Development Capability: Based on long-term industry experience and customized product development capabilities, it has a certain technology research and development team and capabilities. It is able to continuously improve product design and production processes to adapt to new market demands for product performance and technology.

Abundant Industry Experience: Established in 2005, with its factories dating back to 2000, the company has over 25 years of manufacturing expertise in various fields including gearboxes, chains, transmission shafts, and transmission line parts. This has enabled it to accumulate a profound industrial heritage and better handle diverse production and market challenges.Professional Customization Capability: Focused on the development of customized OEM products, it can conduct personalized production based on specific customer requirements, meeting the diverse needs of the market. It demonstrates strong flexibility and adaptability in market competition.Excellent International Reputation: Thanks to its sincerity towards customers, high sense of responsibility for orders, and long-term cooperation experience with foreign clients, the company's products are widely popular in the European market. It has won the trust of customers worldwide, and its brand influence is continuously expanding.

Diversified Product Portfolio: Covering a wide range of products such as various types of conveyor chains,PTO shafts, sprockets, gears, couplings, V-pulleys, , and worm gear reducers. These products are widely applied in industries like sugar, cement, mining, food, water, wood, automotive, and palm oil, providing one-stop product solutions.High-Quality Product Assurance: The production process employs modern equipment manufacturing and strict quality control measures. This ensures stable and reliable product performance, reduces customers' failure and maintenance costs during use, and improves production efficiency.

Quality After-Sales Support: Possessing a professional engineer team for after-sales service, it can promptly address problems encountered during product usage, offer technical support and solutions to customers, ensure the continuity of production, and enhance customers' confidence in using the company's products.Rich Information Provision: With a news and blog section, it shares industry knowledge and FAQs, such as chain rust issues, common problems and solutions for conveyors, chain quality judgment methods, and gear tooth number design. This provides customers with valuable technical information and purchasing guidance, helping them better understand the products and industry trends, reflecting the company's professionalism and care for customers in the industry.

Copyright © Hangzhou Ocean Industry Co., Ltd. All Rights Reserved