Here we introduce Ocean Conveyor chains, Link conveyor chains. They are like strong and trustable assistants which work in the front lines as a team to make things done efficiently and safely. This lesson is going to help you understand more about link conveyor chain, discover the different types you can use for different jobs, how to get the most from a good system, tips to keep them in good order, and some key factors to consider when choosing the right one for your technical needs.

When it comes to the transport of goods and materials, link conveyor chains have a range of benefits. They are made from natural artifacts that have been designed to be incredibly durable and not break easily when holding heavy objects. This means they can be trusted to relocate the items safely from one place to another without any kind of glitches. Conveyor chains are also very dependable, meaning from day to day they function the same without fail. They help the in-house team do the job—but for beginners, they are like the backbone of a successful operation. This is very useful in a busy environment when there are a lot of items required to be relocated in one go.

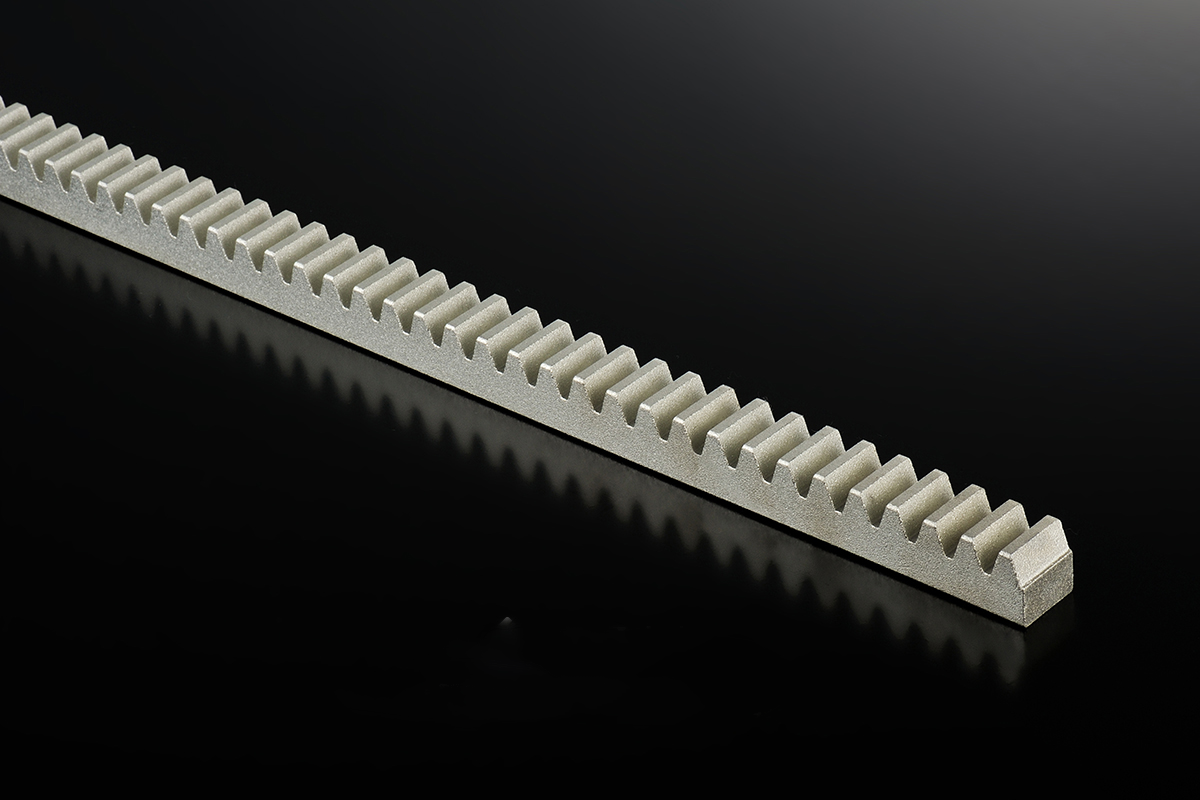

Link conveyor chains come in multiple types, all of which serve different uses and tasks. For example, roller chains are ideal for transporting heavy objects over long distances, so they are commonly found in factories and warehouses. For lifting and pulling operations, and in situations where it is necessary to move something up or down, however, the leaf chain is well suited. Also, smooth running and accurate placement of block chains well suits applications area like assembly lines or automated machines. Knowing the different kinds of Ocean link conveyor chains and their properties, you would be able to get the one that is ideal for your requirements and tasks.

To get the most out of a Ocean link conveyor chain system in terms of productivity, it is highly critical that the link conveyor chain system is fully well-functioning with all its parts and components. Proper maintenance and inspection can keep this system running, thus preventing breakdowns. This Drive chains involves routine checks of various components to ensure that all is functioning as it should be. Training employees on system usage and safety protocols is to avoid accidents and disruptions. As such, you have to enable the personnel to know the way to safely operate the conveyor chains to maintain both safety and productivity. As such you will be able to invest in a legacy link conveyor chain system, but with the understanding that you fuel yourself in its upgrades too.

With the proper maintenance, your link conveyor chain can last a long time. Checking the condition of your chain regularly can allow you to catch issues before they turn into bigger problems. That means checking for any damage or parts that don’t appear correct. Lubricating the chain on a regular basis can also reduce friction, which can help extend the life of the chain. Cleaning the chain and removing dirt or debris will help prevent damage to the bike and will help due to the bike moving nicely and freely. Keeping your link conveyor chain on were it needs to be is crucial for preventing expensive repairs—these maintenance tips will help keep your chain in shape. Caring for your equipment will save you money and make everything run better.

Fortunately, when it comes to your business, there are a number of features you should pay careful attention to when selecting a link conveyor chain. The first thing is to ensure that the size and strength of the chain suits the weight and size of the load you are going to be shifting. An important thing is, if a chain is too weak it gets broken and causes troubles. The chain itself must have appropriate materials that accommodate to wear and corrosion, that way the chain is able to withstand the harsh conditions without breaking. Furthermore, with the design of your Engineering chains, it should be designed to align with your unique application and environment, so it should be well suited for the processes you want to carry out. In addition, you have to think about speed or load or flexibility, etc.-how it meets your needs. If you consider these key elements, you will be able to select the right one for your business and get the best performance possible out of it.

Quality After-Sales Support: Possessing a professional engineer team for after-sales service, it can promptly address problems encountered during product usage, offer technical support and solutions to customers, ensure the continuity of production, and enhance customers' confidence in using the company's products.Rich Information Provision: With a news and blog section, it shares industry knowledge and FAQs, such as chain rust issues, common problems and solutions for conveyors, chain quality judgment methods, and gear tooth number design. This provides customers with valuable technical information and purchasing guidance, helping them better understand the products and industry trends, reflecting the company's professionalism and care for customers in the industry.

Abundant Industry Experience: Established in 2005, with its factories dating back to 2000, the company has over 25 years of manufacturing expertise in various fields including gearboxes, chains, transmission shafts, and transmission line parts. This has enabled it to accumulate a profound industrial heritage and better handle diverse production and market challenges.Professional Customization Capability: Focused on the development of customized OEM products, it can conduct personalized production based on specific customer requirements, meeting the diverse needs of the market. It demonstrates strong flexibility and adaptability in market competition.Excellent International Reputation: Thanks to its sincerity towards customers, high sense of responsibility for orders, and long-term cooperation experience with foreign clients, the company's products are widely popular in the European market. It has won the trust of customers worldwide, and its brand influence is continuously expanding.

Advanced Production Equipment: Utilizing modern equipment in the production process to ensure high-precision and high-quality production of products, improve production efficiency and product consistency, and maintain a technological edge in the fierce market competition.Technology Research and Development Capability: Based on long-term industry experience and customized product development capabilities, it has a certain technology research and development team and capabilities. It is able to continuously improve product design and production processes to adapt to new market demands for product performance and technology.

Diversified Product Portfolio: Covering a wide range of products such as various types of conveyor chains,PTO shafts, sprockets, gears, couplings, V-pulleys, , and worm gear reducers. These products are widely applied in industries like sugar, cement, mining, food, water, wood, automotive, and palm oil, providing one-stop product solutions.High-Quality Product Assurance: The production process employs modern equipment manufacturing and strict quality control measures. This ensures stable and reliable product performance, reduces customers' failure and maintenance costs during use, and improves production efficiency.

Copyright © Hangzhou Ocean Industry Co., Ltd. All Rights Reserved