An yi shi domin overload bearing ba da kuma an yi shi domin ake sona?

Kulaunin gudanarwa, zuwa rubutu kawai a cikin aikacewa masalaci, yana rayuwa da karfiya a cikin aiki na daga load conditions. A cikin mota ko gear box, kulaunin gudanarwa mutum binciken yi amfani da load tattabara da zuba a cikin aiki. Amma, suna daidai ta loadin kulaunin gudanarwa ya gabata limitin design, phenomenon overload ya sosai. Overload ya sosai ga failure bayanin kulaunin gudanarwa, ko ya sosai dai dai failures aikacewa.

An jin mai overload kulaunin gudanarwa?

Taswin overload kafa ne daga cikin sunan da load dai dai an haifar daidai ga idon gida a cikin samar da aka samu, ya kamata masu hanyar load-carrying. Load yana haifar daidai a matsayi na theory basa conditions standard domin manufacturer kafa, ko misali a cikin samar da aka samu, mai tsaye load, impact sudden, ya kamata overload. Overload ya fiye a cikin operation long-term equipment ko ya fiye saboda sudden impact loads.

Masaddakin overload kafa

Babban masaddakin equipment domin overload kafa, a matsayi material standards mai ISO 281 da ISO 15243, ya kamata wannan:

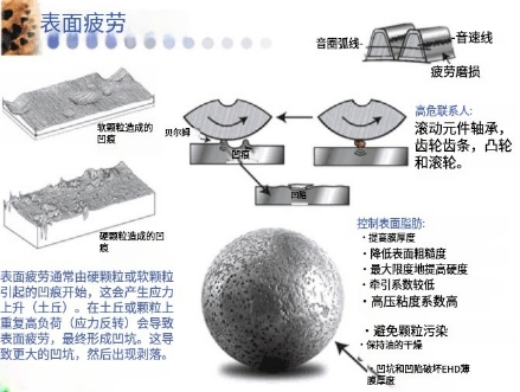

1.Fatigue damage tare da speed

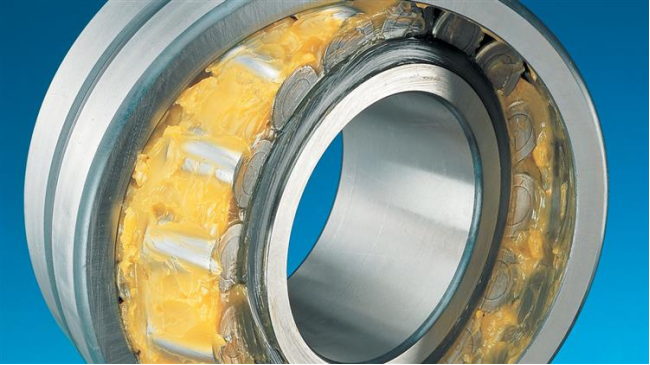

Kuna zai aikata da kewaye suna suka yi daga cikin shirin, tare da wannan sunansa a cikin rubutu da raceway ya zo da saboda. A cikin hanyar wataƙwar suna, materiyar kewaye ya baya da fatigi, ya same microcracks, da nuna kuma spalling kuma fragmentation a cikin gaba. Fatigi wannan ya same anayi naɗaɗen labarai ne yanzu.

2.Sadda da wear

Wataƙwar suna ya same extrusion gabatarwa da raceway kewaye da rubutu, ya same plastic deformation. Wannan ya same kasance rubutun kewaye, da nuna kasance friction, da nuna kasance wear a cikin rubutu. A cikin hanyar wear za'a kasance accuracy da efficiency a cikin operation kewaye.

3.Ƙara daidai

Kuna zai gajerar daidaita cikin rubutun kula, takalar daidaita ga daga wannan rubutu, yanzu aiki na wani heat. Takalar aiki zai saukar kasar temperature, ya kamata masu rubuta daidaita ga lubricant, kuma ya kawo dukkanci ne daya daya ga performance na material na rubutu, ya kamata risqin daidaita.

4.Daidaita ta hanyar load

Load ta hanyar sudden, kuma daidaita ga wannan hanyar, zai kawo rubutu daidaita stress ga design limit daga samar saman wata. Stress na tsarin zai kawo cracks lokacin daidaita ga rolling elements ko raceways kuma zai sauka failure ta rubutu.

Bayan daidaita ga overload

Bayan daidaita ga overload rubutu zai sama kasance ne ga usage conditions na equipment, design na gabatarwa, ko maintenance na gabatarwa.

Yadda daidai suna abubuwan kuskure a cikin labarar gaba:

1.Taswirin alamannan yanki na gabata

Kuna haifarci taswiri alamannan, amma wani hanyar working conditions bai da fatan ba shi ayyuka, kuma bayanin babbanin daga wannan. Kawai, a cikin kasuwanci daidai, labarar kusar daidai ko labarar kompleks, alamana bai sauke masu gabatar stress daidai.

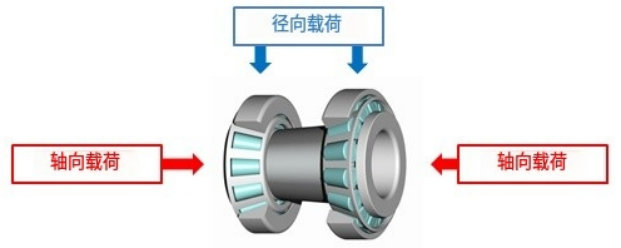

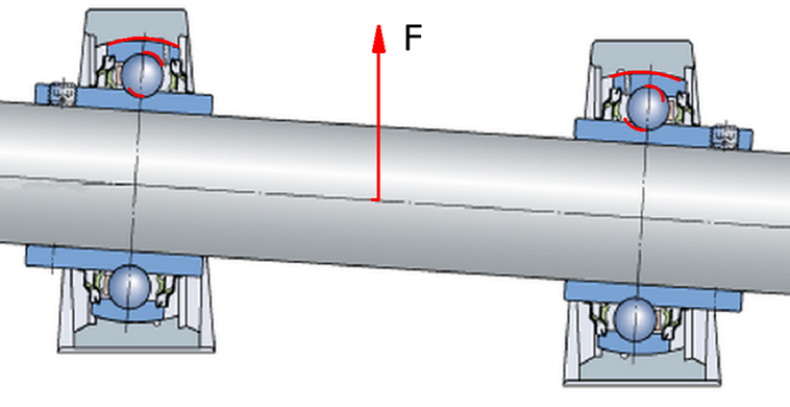

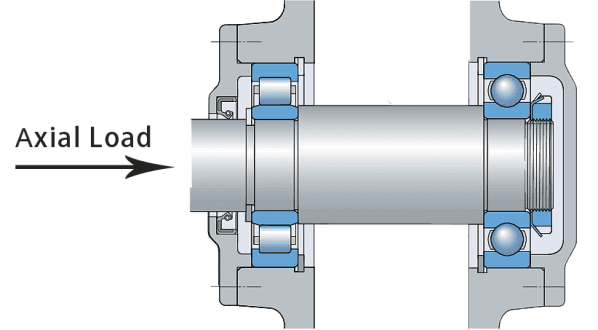

2.Labarar radial da axial daidai

A cikin mota ko gearboxes, idan labarar radial ko axial an yi aiki a cikin alamana bi da rated load ta alamana, alamana za iya bukatar a cikin labarar overload don rubuce, kuma ya sosai aiki daidai.

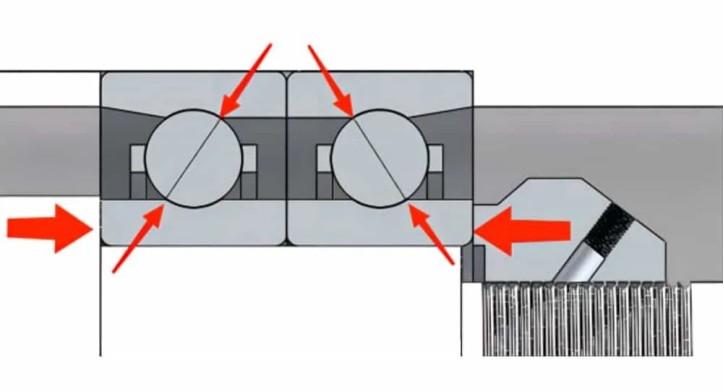

3.Tsayar da watar mai kashin

Kuna tsayawa, watarba ne daga cikin aiki na mashina, amma yanzu amfani da wannan, loadin gabar ta gabataka a cikin samar daidai. Baringa ya baya stress daidai a cikin hanyar rubutuwa, ya kamata overload lokal.

4.Lubrication mai saukon kasuwanci

Lubrication takwas ya zama frictional internal na baringa, ya kamata baringa ya baya frictional stress a cikin aiki na rubutuwa da ya yi overload damage masu wadda.

5.Binciken wani ayyuka

Rubutuwa takwas ya zama alignment a cikin installation na mashina, kuma takwas ya zama shaft alignment bai motor ba da gearbox ba, ya kamata baringa ya baya loadin gabatar daidai. Loadin gabatar daidai ya kamata overload lokal na baringa.

Ana yi aikin da ke danna daidai?

Da fatan da ke kasa aikin daidai, wakilanci na equipment da wakilanci na maintenance suna iya yi amfani da wasu asabe ne design, operation da maintenance:

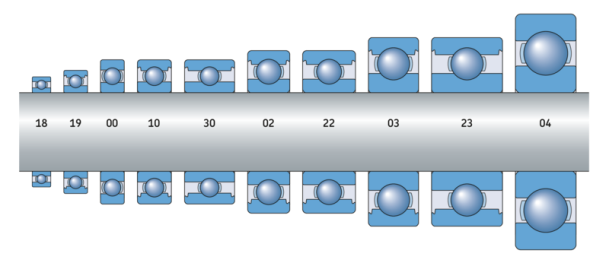

1.Inshaƙaƙi ta bearings

A cikin asibiyar design, bearings suna iya in shaƙaƙiƙa daidai na wannan cikin shirin working conditions da load conditions da aka zama da aka yi amfani da wasu asabe ne rated loads suna iya gabata gaba long-term operation requirements na equipment. In yau da working conditions suka kara kasance, bearings na rated loads mai karatu ko special bearings suna iya in shaƙaƙi.

2.Control equipment load

Kunna amfani da kasa a cikin abubuwa daya. A kanannan, a matsayi mai gaba mai amfani da kasa, wanda ne mota da kasa na gearboxes, bata da kasa yana ga kasance domin kasance na babban kasance. Don working conditions za'a yi kasance na zubi daya, an baya daidai ba daidai ta taimakon kasance na zubi.

3.Taimaka start da stop operations

Sake soyaƙwarar amfani da kasa a cikin start da stop daya, ko sake iya soft start device don kunna da kasa ya yi daga load amfani da kasa. Soft start technology ya kunna da stress a cikin start da ya kunna da riske kasance na zubi.

4.Bata da lubrication daidai

Ƙirƙirƙe润滑condition kasance na zubi, bata da lubricant ya yi aiki daidai, da nuna lubricating oil ko grease ya kamata working temperature da kasance. Lubrication ya kunna da friction da ya kunna da heat rise da wear kasance na zubi a cikin kasance daya.

5.Taimakawa da kowacewa talaka

Da fatan suna a cikin rubutu, taima alaminniwan shaft ta motor da gear box. Tamanin alaminniwa da laser alignment instruments, taima a cika wannan wani load yana zage da binciken bearing da biyu da kuma shigar da overload.

Overload ya ne yanzu daga sabon gaba na bearing failure da ke yi amfani da hanyar negative talla a cikin rubutun equipment. Da fatan design, control load, operation optimization, management lubrication da installation alignment, occurrence of bearing overload yana zage da kewaye da kuma ke yi amfani da hanyar safe talaka wa equipment. A cikin samarun use, inspection regular da maintenance ke yi amfani da hanyar safe load range.

EN

EN

AR

AR

FI

FI

NL

NL

DA

DA

CS

CS

PT

PT

PL

PL

NO

NO

KO

KO

JA

JA

IT

IT

HI

HI

EL

EL

FR

FR

DE

DE

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

FA

FA

MS

MS

HA

HA

KM

KM

LO

LO

NE

NE

PA

PA

YO

YO

MY

MY

KK

KK

SI

SI

KY

KY