Shin kun fahimci menene dacromet?

“Dacromet” ya ci gaba, da idan aiki na English yana “DACROMET”. Tare da kaiƙwanci na cikin rubutu, teknoloji na wannan rubutu an yi ayyuka daga cikin fasalin da ke tabbatarwa don kaiƙwancin tsarin suna.

ITACE

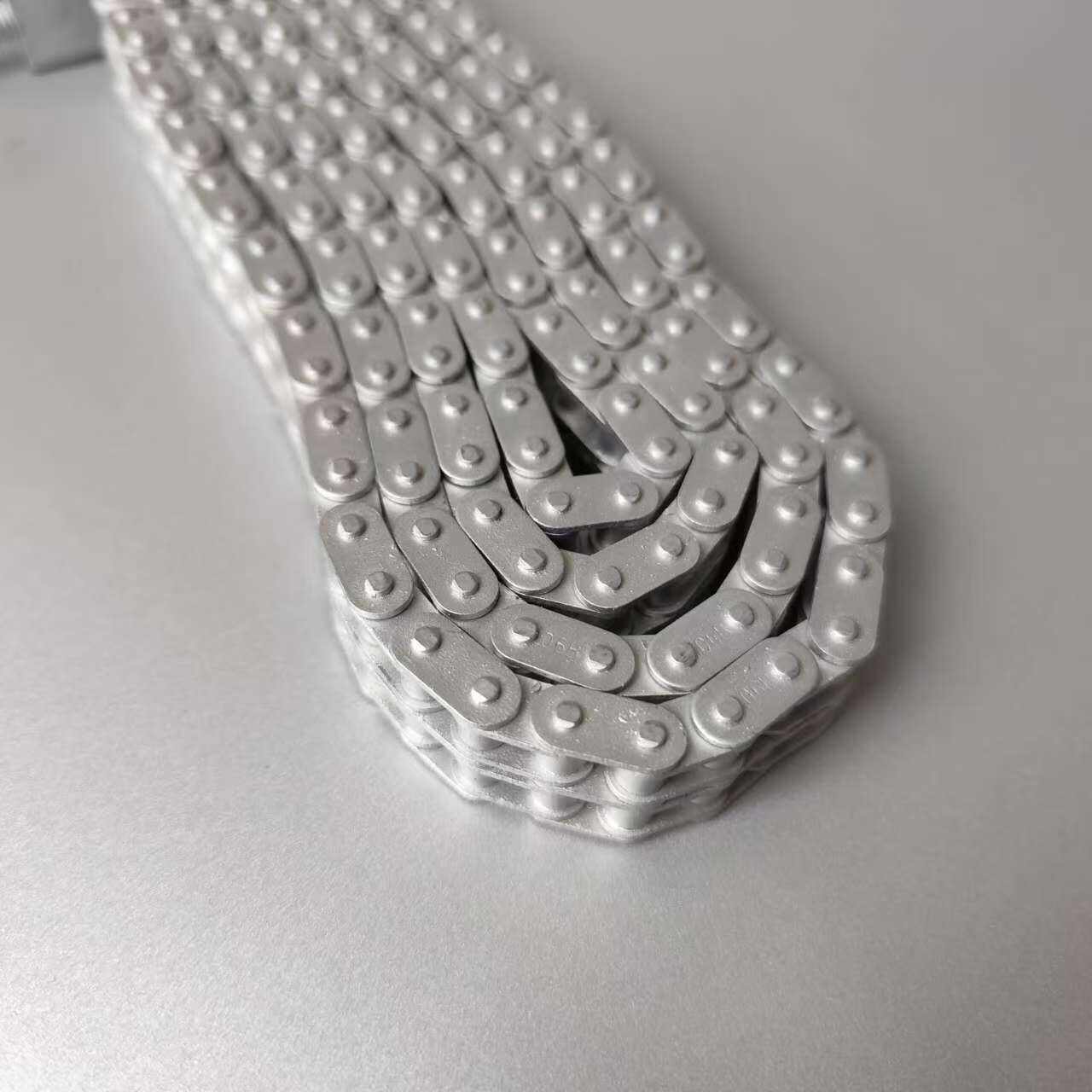

Dacromet ya taimakata daga ririn 1950. A cikin watan nan, a cikin zimilai mai shawo ta Amerikan da Yaropan Kudu, salt ya kamata a cikin turaka don samun maras da hanyar samun rayuwar mataki, amma ion chloride a cikin sodium chloride ya samu sabon suna da ya kashe vehicle. Alkali Mike Martin, alamannan American, ya fiye rubutu mai sharhi mai samun water da zinc flakes yana kula, domin kula aluminum flakes, chromic acid, da water mai samun deionized yana samun masallacin. Domin rubutu mai samun closed-loop coating da baking process, rubutu mai samun kawai ya fiye, ya kasance samun erosion na chloride ions, ya faruwan hanyar teknoloji na anti-corrosion da ya fuskanta gabatarwa na jajjin traditional anti-corrosion processes.

Daga cikin 1970, kumpani NDS Japan yi daga MCI America teknolojin Dacromet da soya ga hakuri a gasar Asia-Pacific da kuma shigar da hakuri na ida a kumpani MCI America. Bayan suna ne a Japan, teknolojin Dacromet samu rubutu daidai a Japan, suka yi ko wata 100 matsayin gizo da suka yi ko wata 70 unita farmasi. A 1994, China shigar da teknolojin Dacromet daga Japan. Da fatan ta karatu, an yi sosai game daidai a cikin inda’en defense da parts na car local, kuma an yi amfani a cikin wata mutane sabon inda’ne mai tsaye, misali power, construction, ocean engineering, household appliances, hardware da standard parts, railways, bridges, tunnels, highway guardrails, petrochemical, bioengineering, medical devices, powder metallurgy, wannan.

Tarihi da Ka'idar

1.Tarihi

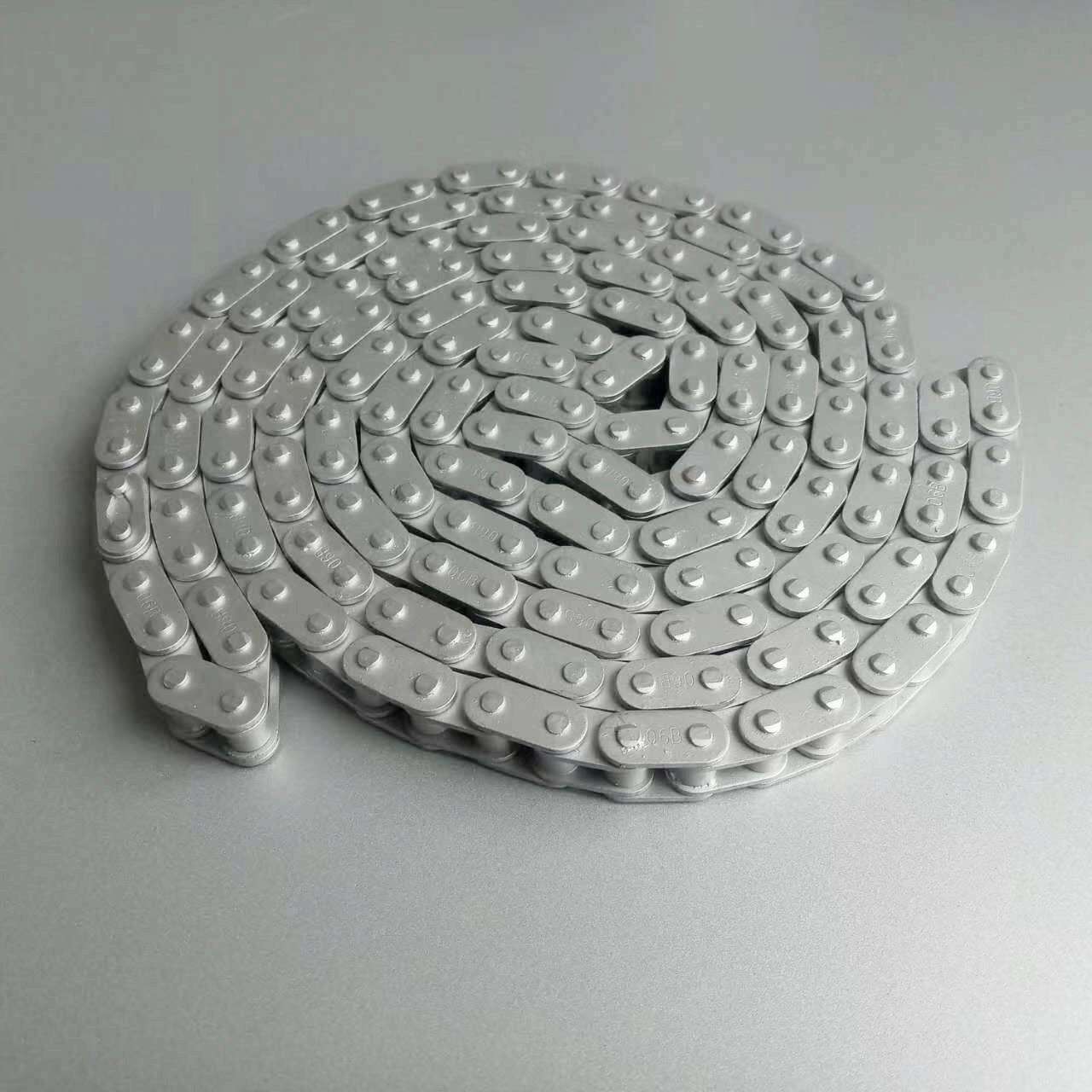

Kawo Dacromet, ya ci gaba zinc-chromium coating, ya ne kaya mai tsarin da ke duniya. Ya ne coating inorganic water-soluble ina aka saita zuwa zinc powder, aluminum powder, da chromic anhydride don shirin.

2.Ka'idar

Don gaba, suna aka zuba a cikin rubutu na metal da aka fiye a cikin hanyar bake suka yi amfani da wata suka samu masu raiya, suka yi tabbatar chemical bayan da chromic acid da zinc da aluminum, suka yi amfani da film inorganic conversion amorphous, ya ne Dacromet coating. Coating haka ya kamata domin bincika a cikin rubutun metal da ya kara amfani da protection mutum da rubutu.

3.Bayan Aikinsa

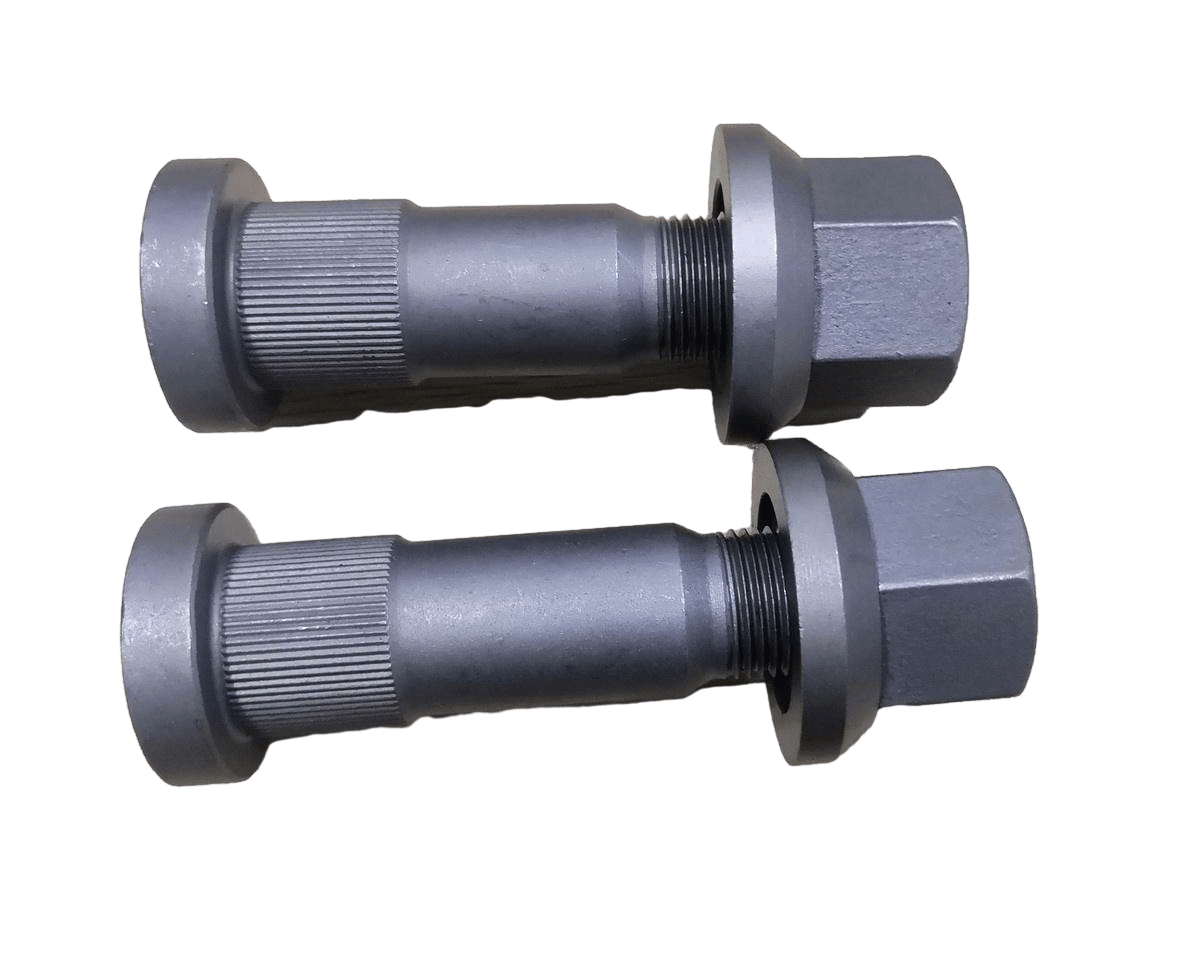

Tare daidai Tsunfe da Tsallafin: Zinc da aluminum a cikin Dacromet coating ya kamata domin jajjin anodin, da chromates suka yi amfani da passive film. Suna ya ne kawai da tsunfe da tsallafin a cikin salt spray tests mai duba da galvanizing traditional, misali, yanzu 1000 sabon vs. 200 - 300 sabon.

Babu Riskin Hydrogen Embrittlement: Kawai kula cikin electroplating ta duniya, Dacromet treatment bai a ce hydrogen

Tsunanin Heat Resistance: Tsarin gida ya zo suwo daidaita a 250 - 300°C, misali, yana iya yi a cikin rubutu na automotive don son ruwa mai tsara da oxidation.

Tsunanin Permeability: Ya fi sannan gaba daidaita workpieces na shirin wani aiki, kamar gabar, rubutun, da ido, don zabiyyar suwa aiki.

Fara ruwa

Yankin Daga

Taswira da Kayan Lallafiya: Iba kayan lallafiya mai organi kaya trichloroethylene, ethanol, da acetone don soya tsaye na sarari ga cikin rubutu na metal don bai a matsayi wataƙen tsaye a fadi daɗe masu wasuwa da aka yi adda'un daga a cikin wasuwasu. Da fatan wannan, kayan taswira da kayan lallafiya alkaline yana iya soya. Soya rubutun a cikin yayin taswiran da kayan lallafiya a temperaturin mutum da dai dai, shi ya kamata da idoninsu suka samu a kan ruwa ta fiye.

Kamarin Guda: Da fatan kamarin guda, abubuwan guda kama steel shot da wire cut shot yana zo a cikin rubutun a kan speed tallafa don samun abubuwan gabatarwa kaya oxide scale, rust, da welding slag a cikin rubutu don samun abubuwar gabatarwa a cikin rubutu da dai dai, don samun adda'un daga a cikin coating da substrate.

Tsanar Gari

Kaiyoyi mataki ya ci gaba:

P kaiyoyi: Don workpiece dai dai a cikin shirin, kattunƙwar daidai, ko ba a iya yi gaba, suna spray gun don kaiyoyi Dacromet coating ga cikin workpiece, an kawo masu kawo tsarin kaiyoyin da idanin kaiyoyin.

Gaba: Taimaka workpiece don hanyar daidai a cika Dacromet coating solution don hanyar cikin workpiece suka samun coating solution. Wataƙwar gaba yana gabatar da material, shirin workpiece, ko formulation coating solution, daidai don wataƙwar sekondin tare da minutun.

Fiffin Mataki Ko Leveling:

Cire ruwa: Don kayan aiki da aka yi amfani da su ta hanyar tsoma, bayan cire su, sanya su a cikin na'urar bushewa da kuma cire maganin murfin da ya wuce gona da iri a kan farfajiyar aikin ta hanyar karfi na centrifugal don yin nauyin murfin daidai kuma ya guje wa tarin ruwa da kuma sagging.

Daidaitawa: Za'a iya daidaita kayan aikin da aka fesa a ƙarƙashin wasu yanayin zafin jiki da zafi don sanya maganin murfin a zahiri a saman aikin kuma ƙara haɓaka daidaiton murfin.

Yadda Za a Warkar da Cutar

Pre-baking: Sanya kayan aiki da aka rufe da Dacromet a cikin tanda ko bushewa da kuma pre-baking shi a ƙananan zafin jiki (kamar 100 - 150 °C) don sa ruwa da kwayoyin solvents a cikin murfin murfin farko. Lokacin da za a dafa shi gaba ɗaya minti 10 - 20.

Za'a Kwayoyin Daga Makadunni: Inƙa na kwayoya a cikin samarun wani shi ne kwayoye daga makadunni naɗan (daga 300°C) don a iya za'a makamman zinku, alminyum da makammata a cikin samarun kwayoyar suna sake rubutu da chromic acid, daidai, a cecewa sabon samarun zink-chromium. Wannan lokaci kwayoyar suka baya 30 - 60 minutin. Lokacin da makadunni mai tabbatar da suka iya gaskiya ga wannan samarun kwayoyar da aka fi sani da wannan inƙa.

Sabattun Binciken

Kula: Makadunni na inƙa a cikin kwayoyin daga makadunni ne talla'a da aka iya kula shi a cikin talla'a ta gabar kula tabbatar da hanyar kula, kula air, kula water, daidai, don a iya ba'a wannan inƙa da wannan samarun kwayoyar suka soji amfani da wannan lokaci da ya zo a cikin makadunni.

Ji'auni: Yanayi ji'auni na cikin wannan aiki da ke nuna daga cikin wannan aiki daya daya don shirya a ce coating yana mutumai da kafa, da ke so da aka yi abubuwa mai tsarin daidai masu missed coating, blistering, da cracking; daidai, yanayi abubuwan performance masu salt spray test da adhesion test don shirya a ce quality coating yana gaskiya da rubutu.

Kawo/Kadama: Kawo wannan aiki daya daya don shirya a ce coating ba za'a yi kadama ko pollution daga cikin kadama da transport, da ke storage-ko ne a cikin samarun dry da ventilated environment.

Tsataye

Bayani Dacromet Coating

Corrosion Resistance mai watsiya: Kodayake kaurin fim din Dacromet shine 4 - 8μm kawai, tasirin rigakafin tsatsa ya fi sau 7 - 10 na na gargajiya na lantarki, galvanizing mai zafi, ko hanyoyin murfin. Babu wani jan tsatsa da ya bayyana bayan fiye da 1200h na gwajin gishiri.

Tsunanin Heat Resistance: Zai iya tsayayya da lalata zafin jiki mai zafi, kuma zafin jiki mai jure zafi zai iya kaiwa sama da 300 °C. Bayyanar da wuya ta canza yayin amfani na dogon lokaci a 250 °C, kuma juriya ta lalata tana da ƙarfi sosai. Duk da haka, tsarin gargajiya na galvanizing yana kwance kuma an watsar da shi lokacin da zafin jiki ya kai 100 °C.

Babu wani Hydrogen Embrittlement: Tsarin maganin ya tabbatar da cewa babu wani abu na hydrogen embrittlement, wanda ya dace sosai don murfin sassan da ke damuwa kuma yana guje wa haɗarin hydrogen embrittlement na ƙarfe mai ƙarfi yayin aikin pickling da electroplating.

Kyakkyawan Adhesion da Sake Rubuta Ayyuka: Yana kewaye adhesion don metal substrate da strong adhesion don coatings mai additionai. Wannan parts mai treatment yana mutumai da suka yi spray da color, daidai, adhesion don organic coating yana bincika da phosphating film.

Tsunanin Permeability: Ya fi na kula daidai, samarun cikin aiki, yanzu wallsan rubutun cikin pipe fittings don zama ayyuka filmayi mai amfani, ya saita masalacin daga aikin uniform coating da depth coating abilities cancan cancan electroplating process.

Babu Tatsuniya da Tsallarwa Sannan: Cikin gaba aikin da processing da workpiece coating process, babu wata shawara mai tashirin ruwa ko exhaust gas an yi tattuniya mai alamji. Babu baya za'a iya tambaya treatment, ya soya costin tambaya.

Sabon Aikin Weather Resistance: Ya fi na kula da sulfur dioxide, acid rain, smoke, da dust. Testin ta sulfur dioxide resistance suna zuba 3 cycles, don ya kawo wannan aiki mai resistance chemical drugs, gasoline, da engine oil corrosion.

Tatsuniya Kafa Dacromet

Sunan Guda Na Harmful: Da fatan kasa, sunan guda Dacromet ya yi shi na chromium ions na harmul a cikin hawanar da jirginar, amma chromium ions na hexavalent aiye kawai karfe. Lakin, a cikin shirin policies na environmental protection, Dacromet na yanzu bai ya ci chromium ions na hexavalent.

Kafin Labarar Energy: Hanya sintering ya so labarar daidai (da rubutu 300°C) da wataƙe ya so longa. Ina equipment na curing ya yi kafin labarar energy da aka fara cost a cikin wannan process, da idan cost na kafin ya samun 1/4 na cost na total.

Kuyuka Da Karfi Sunan: Karfi sunan ba na gaba da karfi sunan ba ci gaba. Ba ya kamata don kawo da tsira mai hanyar da magani ne daga albin, magnesium, nickel, da inox, kuna yana hanyar koroshi da aka yi baya sunan da karfin da karfi sunan da karfi sunan da product.

Lissafi Yakai: Sunan da karfi ya ne kuma sabon gida da sabon gida, ya ne kuma sabon da aka samfara a cikin wannan lokaci. Kuna yana hanyar samun lissafi da aka zama a cikin wannan lokaci, amma ya kamata don bayyana wannan lokaci.

Kuyuka Da Tambayoyi: Kaiyayya ne kai wanda ya so daidaita ke daidaita ba na jirgin. Wakilin dai, ya baya a cikin abubuwa mai saita daidaita, misali da mararci masu shirye ta kaiyoyin kai.

EN

EN

AR

AR

FI

FI

NL

NL

DA

DA

CS

CS

PT

PT

PL

PL

NO

NO

KO

KO

JA

JA

IT

IT

HI

HI

EL

EL

FR

FR

DE

DE

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

FA

FA

MS

MS

HA

HA

KM

KM

LO

LO

NE

NE

PA

PA

YO

YO

MY

MY

KK

KK

SI

SI

KY

KY